|

If you are a handmade pottery collector like me, I run out of cabinet space quickly as my collection grows. As my wife and I outgrew our kitchen cabinets, we thought of ways to display our selection of handmade cups and mugs that would require less effort than ripping out our cabinets and replacing them with an open shelving concept. Another thing about me that you may or may not know, I am a cheap ass. I'm not looking to spend $200+ on a cool shelving display that isn't just some cookie cutter laminate shelving unit or adding a few horizontal shelves to the wall. A boring shelving unit can cheapen the contents inside it, so I decided to use my planning, design, and woodworking skills to come up with something that didn't cost too much. The result is the image you see above that holds 35 pieces of varying sizes and shapes to make one hell of an interesting wall piece! I'm going to walk you through the materials, tools, and steps required to make this same mug shelf so you can display your handmade collection inside it's own work of art. If you are a maker yourself, I don't have to tell you how much more you appreciate something when you put the planning, time, and struggle into building something yourself. Let's get to it! Materials: All materials needed can be purchased at your local Lowe's, Home Depot, or similar hardware store.

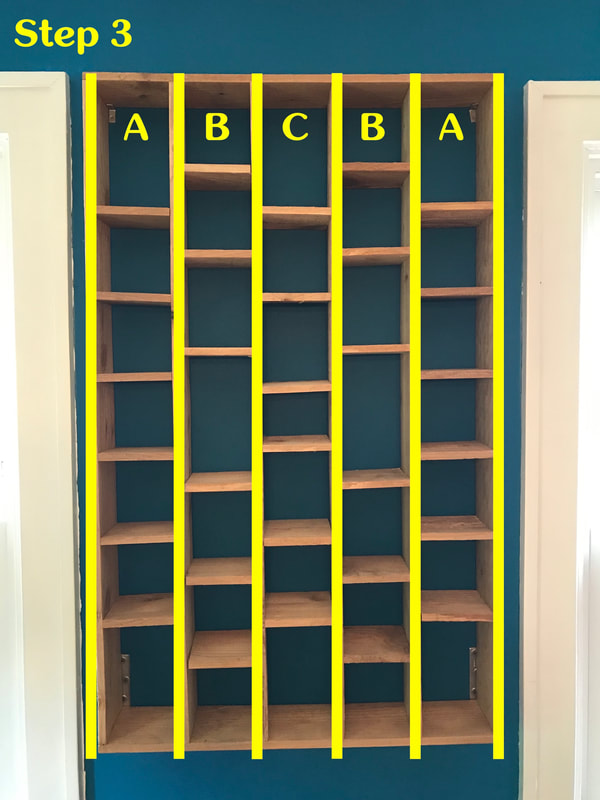

Steps to Build: There are a few ways you can build this unit. The process I walk through below is not the exact same steps I took when building this unit myself. This process was adapted from the larger shelving unit I just completed that was double the size of the one I'm showing here and I think it should be easier for you to get more precise and square shelves overall than the steps I did my first time. 1. Cut 6 pickets measured at 48" long with chop saw 2. Cut 30 pickets measured at 5-1/8" long with chop saw using remaining wood from Step 1. Use additional picket afterwards if necessary. Pro Tip: I would recommend measuring & cutting them one at a time. I found inconsistencies if I laid out the measurements on one long board and cut all of them afterwards. The saw blade is going to remove a fraction of your measurement with each cut and each one you cut will be a little shorter than the last one. Cutting them one at a time will ensure precise measurements across all 30 shelves. 3. Before we start assembling, let's go over how shelf placement is determined for each column. We have 2 pairs of matching columns and 1 central column that is different than the others. I will try to depict this easily by labeling each column with a letter: A, B & C. Columns labeled 'A' will have the small shelves added in the same spots vertically as the other column labeled 'A.'

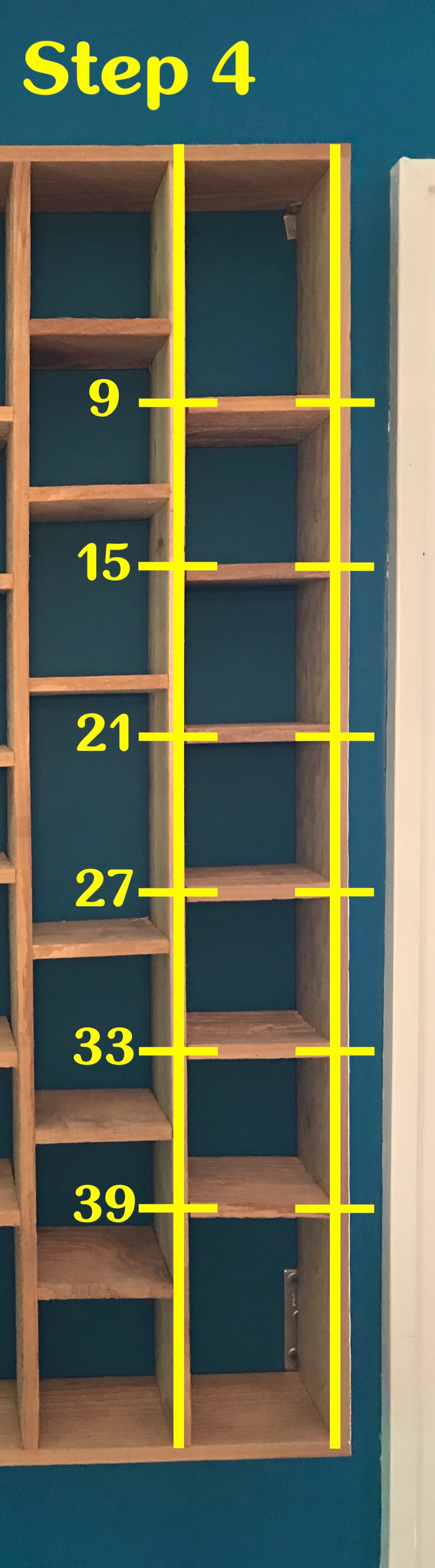

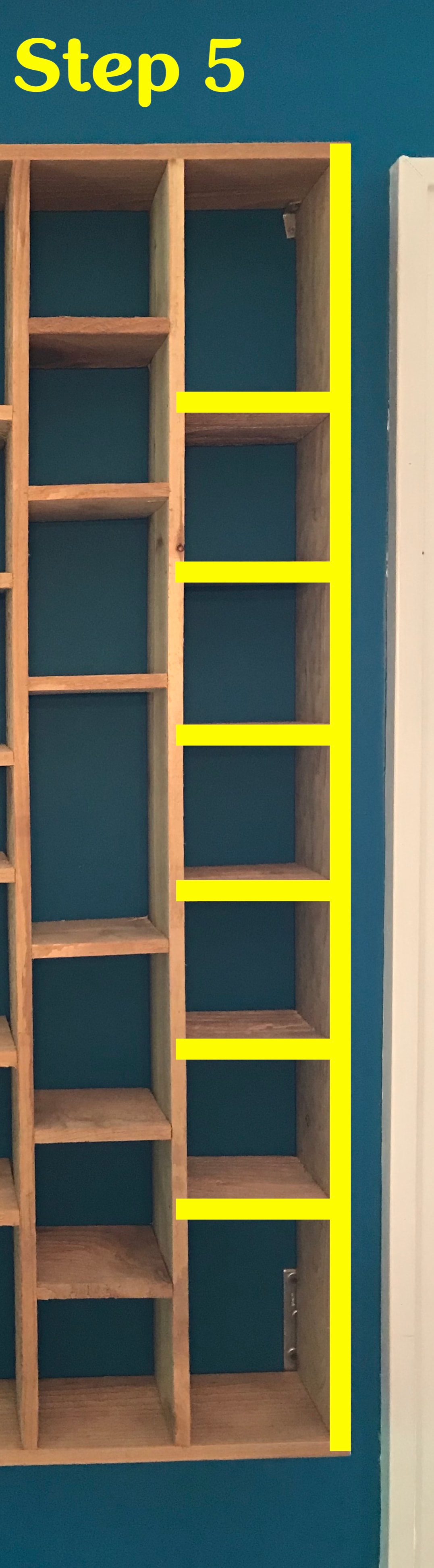

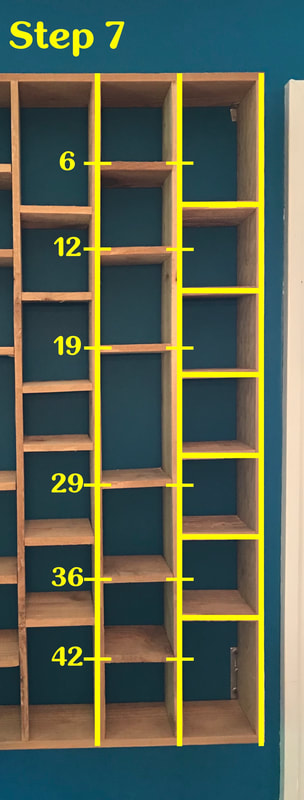

8. The next steps are basically repeating Steps 5-7 above until you get each column attached to the previous one. You should be able to nail each shelf in place by positioning the nail gun inside the adjacent column's cubbies and shooting a nail about 1 inch from the edge of the vertical board. This takes some practice, but be patient. 9. The last column to attach is column C before you will do the same measurements as you did in the previous 2 columns. Column C measurements are as follows: 9", 15", 21-3/4", 26-1/4", 33", & 39". You can see this column is very similar to the measurements for column A, but I wanted the middle one to be a little different than the others just for fun & aesthetics. 10. Once you have all of your columns nailed together, the last thing you need to do is cut & attach the top and bottom of your shelving unit. If everything is square and consistent, the measurement from your left edge to the outside right edge should match on both the top and bottom. Make a note of the width and mark it on one of your uncut pickets. It should be about 30" wide. Cut the first one, then measure, mark and cut the second one. Nail those onto each vertical column with 2-3 nails each. You can optionally use the 1-5/8" wood screws when securing the top and bottom if you'd like it a bit stronger, especially at the 4 corners of the unit. 11. You are done! See the image/PDF below for all the specifics if you would like to save or print it when you build your own. Words of Wisdom:

Thanks so much for following along and I hope you feel empowered to build one for yourself now! If you do build one, please share it with me on Instagram @rdceramics. I can't wait to see your results! If you would like a PDF of the two images above, download them below. I may compose the steps above, including images, into a PDF in the future if you'd like. I'd love to hear any feedback you may have or ideas you would like some insight on for future blogs.

|

Ryan DurbinMy thoughts and findings while I grow as a maker, small business owner, and artist. Archives

July 2022

Categories

All

|

|||||||||||

Proudly powered by Weebly