|

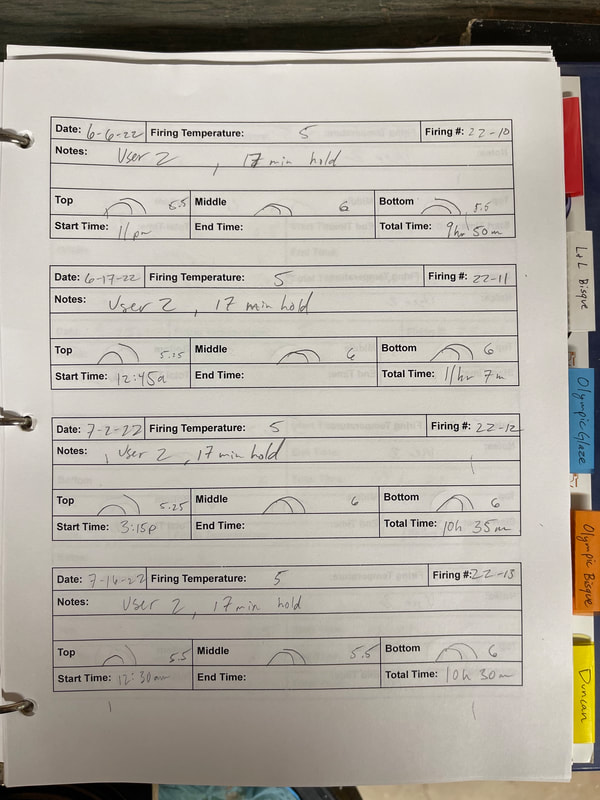

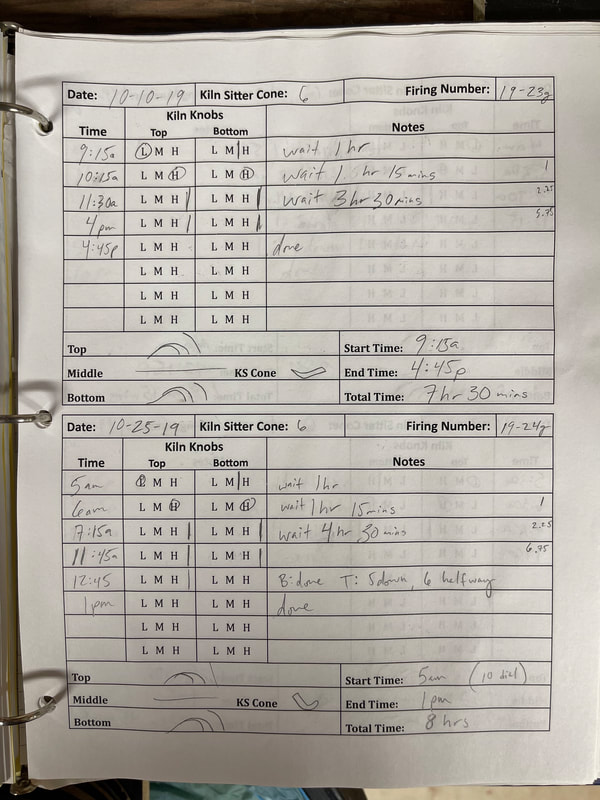

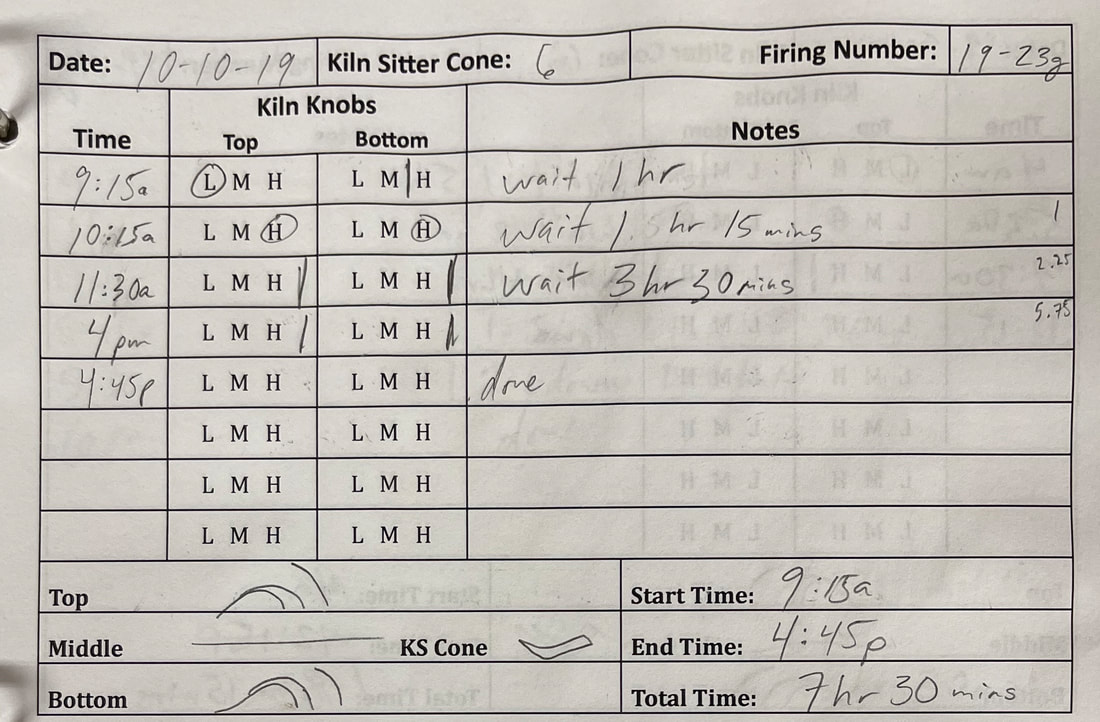

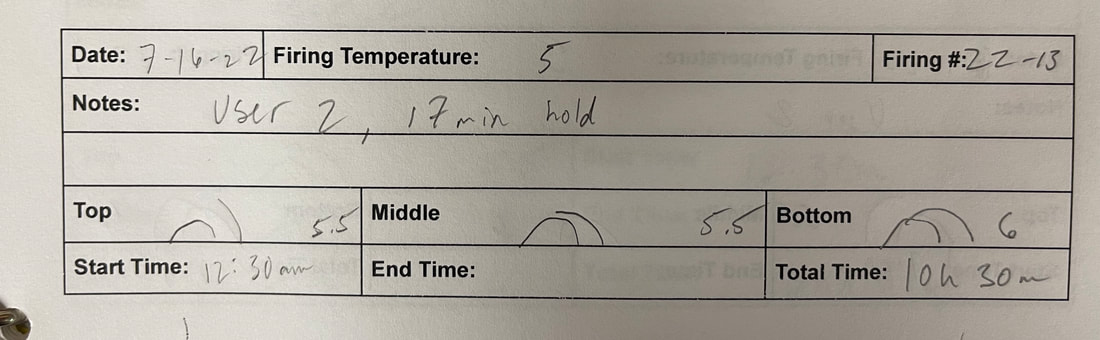

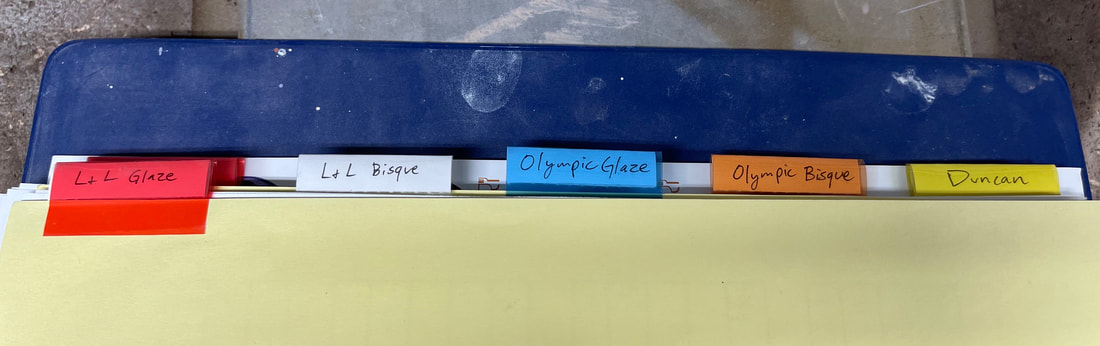

This post is going to be all about keeping records of what's going on with your kiln firings. There are many reasons to keep track of your firings, but I'll share why I do it and continue to do it after having a home studio and firing my own oxidation kilns since 2013. The bottom of this post includes downloadable Word docs and PDFs of various kiln logs you can print for your own studio and adjust them if you'd like to suit your own needs. These were all made for firing in oxidation, but they can be adapted for gas or atmospheric firings as well. I'm a very to-do list type of person so keeping great records of each kiln firing is just who I am. For me, it takes a lot of the guesswork out of my studio process if something were to go wrong. Kiln logs help me see when my firings are taking longer than expected, what settings help me achieve desired results/temperatures in the kiln, how many firings my elements/thermocouples/relays have under their belt when it gets time to change them, and how many firings I've had in the year if I need to deduct energy costs for tax purposes. My First Kiln My first kiln was a manual Skutt kiln with a kiln sitter that I got for free at the end of college back in 2013. I still believe a used kiln sitter kiln is the best option for someone building out their home studio for the first time. For one, you can save quite a bit of money by finding them used off Craigslist, Facebook Marketplace, Facebook groups, or family/friends who may have one sitting around in their garage/basement not being used. Second, and more important in my opinion, you learn the basic fundamental workings of a kiln and how to maintain it; including how to change elements, relays, thermocouples, test if the elements are working or not, kiln ventilation options, how to load a kiln effectively, and how to fire it to your desired result. Manual Kilns If you have a manual kiln with a kiln sitter, this is where you should be keeping the best records during your firings because I've found that these kilns can have a wider variation from top to bottom temperatures throughout a firing cycle because they do not include a thermocouple. I've always fired with an Orton VentMaster to vent my kilns so this could play a factor in the heat difference, but I believe the simple fact that heat rises is the primary factor that usually meant the top half would fire hotter than the bottom half. Temperatures in each section/ring of a manual kiln are completely dependent on how far you turn each knob that corresponds to the element it powers. This post isn't necessarily going to get into firing schedules per-say, but generally I would always start the bottom half of my kiln an hour or so before starting the top half of my kiln or turn the bottom knob higher than the top knob when starting the kiln so I achieved a comparable top temperature by the end of the firing. One other strong recommendation I have for firing a manual kiln is to use witness cones within sight of your top and bottom peeps as you fire the kiln. This is the only true temperature reading you will have to know whether that particular section of the kiln is getting to temperature during the final stages of your firing. Manual Kiln Log Details This is going to breakdown how I use the kiln log above and what it tells me about this particular firing. I'll work my way through this from top left to bottom right. Top Section Date of the firing, Kiln Sitter Cone that was placed in the sitter, Firing Number [year]-[quantity in that year][g=glaze, b=bisque], this would be the 23rd glaze firing in this kiln from the year 2019 Middle Section Time that I performed a particular action, Kiln Knob settings from Low-Med-High, Notes that were pertinent, I started the kiln at 9:15am by turning the Top knob to Low and the Bottom knob halfway between Med and High, then waited 1 hour Bottom Left Section Top shelf witness cone results at the end of the firing, these would have been cones 5, 6, & 7 for a cone 6 firing Middle shelf witness cones if any, KS Cone (Kiln Sitter) result at the end of the firing, this would have been cone 6 Bottom shelf witness cone results at the end of the firing, these would have been cones 5, 6, & 7 for a cone 6 firing Bottom Right Section Start Time of the firing, End Time of the firing, Total Time of the firing I sometimes will also make notes above or below these individual firings if I have performed any major maintenance on the kiln like replacing elements, relays, or thermocouples. It's important to know the date when you replace these so you have an idea how many firings they have run since they were last changed. Get a blank copy of the manual kiln log at the bottom of this blog post so you can use it in your own studio. Digital Controller Kilns I bought my first digital controller kiln (Olympic 2323HE) in 2015 after I realized I needed more room to fit my functional work and a more consistent firing schedule that I didn't have to babysit by being right by the kiln for 7+ hours at a time. I bought it used and still have it to this day in my home studio. The great thing about kilns with a digital controller is they tend to be very "set it and forget it" to a degree and fire pretty consistently from one firing to the next. You don't necessarily have to be around for the whole firing and your kiln log doesn't need to be too elaborate either since there are no knobs involved. The controller deals with all of the elements' power, depending on the reading it gets back from the thermocouple inside the kiln. There is more you have to understand in regards to firing schedules, troubleshooting controller errors, and a little more wiring when it comes to kiln maintenance but it shouldn't be overwhelming if you've already owned and maintained a manual kiln in the past. I still recommend using a couple witness cones for your glaze firings (5 & 6 for a cone 6 firing for example) and every few months using a single witness cone for your bisque firings. Digital Controller Kiln Log Details This is going to breakdown how I use the kiln log above and what it tells me about this particular firing. This one is much simpler than the manual kiln log. Top Section Date of the firing, Firing Temperature from the firing schedule I choose, Firing # [year]-[quantity in that year], this would be the 13th glaze firing in this kiln from the year 2022 Middle Section Notes that were pertinent to this firing. On my Bartlett controller, I used the Vary-Fire Enter Prog options and selected User 2 (this is a custom firing schedule, you can store up to 6 custom schedules on the Bartlett Controller) that includes a 17 minute hold once it reached cone 5. Bottom Section Top shelf witness cone results at the end of the firing, Middle shelf witness cone results, Bottom shelf witness cone results. These would have been cones 5 & 6 for attempting to reach cone 6. Start Time of the firing, End Time of the firing, Total Time of the firing I sometimes will also make notes above or below these individual firings if I have performed any major maintenance on the kiln like replacing elements, relays, or thermocouples. It's important to know the date when you replace these so you have an idea how many firings they have run since they were last changed. Get a blank copy of the digital controller kiln log at the bottom of this blog post so you can use it in your own studio. Organizing My Logs Today, I have 2 kilns in my home studio that I have digital controllers (L&L and Olympic). I like to organize my logs in a single 1" binder with multiple tabs with the kiln and firing method to allow me to easily compare trends over time and look back at previous schedules used. You can see all of these organized by tabs in the image below, plus one for my old manual kiln (Duncan) that I keep for reference if anyone asks about firing schedules for a manual kiln. Downloadable Kiln Logs And now for the main reason you came here. Below are all the .doc and .pdf versions of the kiln logs I've used over the years. Please download and share whatever is useful for you or anyone interested in using them. The DOCX versions should be easily editable using Microsoft Word, Mac Pages, or Google Docs. Manual Kilns

Digital Kilns

|

Ryan DurbinMy thoughts and findings while I grow as a maker, small business owner, and artist. Archives

July 2022

Categories

All

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

Proudly powered by Weebly